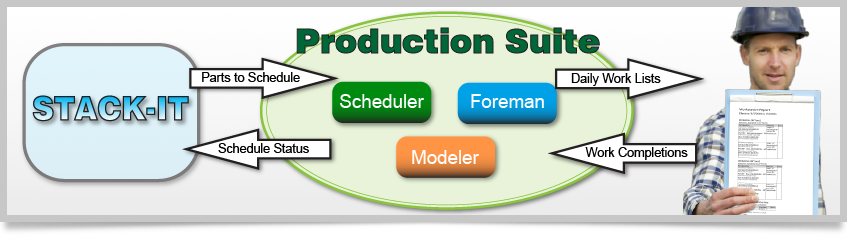

Scheduler

Scheduler is where the heavy lifting happens. This is where all of your work submitted from STACK-IT will be automatically added to your factory schedule, and where manual changes to your factory schedule can be made.

Classic Waterfall

The Part View Panel will be the most immediately familiar, and is where you can see your traditional "waterfall" schedule.

From here you can view details about every operation on your schedule.

There are several ways to view your factory in Scheduler.

Classic Waterfall

The Part View Panel will be the most immediately familiar, and is where you can see your traditional "waterfall" schedule.

From here you can view details about every operation on your schedule.

There are several ways to view your factory in Scheduler.

Multiple Views of your Production

The upper portion of Scheduler gives you three distinctly different ways to view your committed production.

Use the Workstation, Flow, and Site views to gain powerful insights into your overall factory loading as well as detailed information about any part traveling through your production line.

Communicate, Reliably

Full integration with Stack-It means easy automatic communication of parts to be scheduled and feedback on their production status. Your production staff will always know what is coming at them and your customer managers and sales staff will have the current status of work in progress for your customers.

Keep pace with Changes

Say goodbye to the headache of finding slots in your schedule to incorporate a last minute change from your customer or any emergent circumstance! Scheduler can make changes to your factory schedule in a fraction of a second to find a spot for the new or changed work.

Got Visibility?

See and understand the current and future state of your factory at a glance. Get the power of a graphical display for your production schedule and workload. Look at your total production, individual workstations, process flows for part and overall flow patterns. Want more from your factory, you need this!

Foreman

Foreman is where the rubber meets the road. View and print the day’s work schedules and process details. As the day unfolds you mark work as complete or request schedule changes, all in one easy to use application.

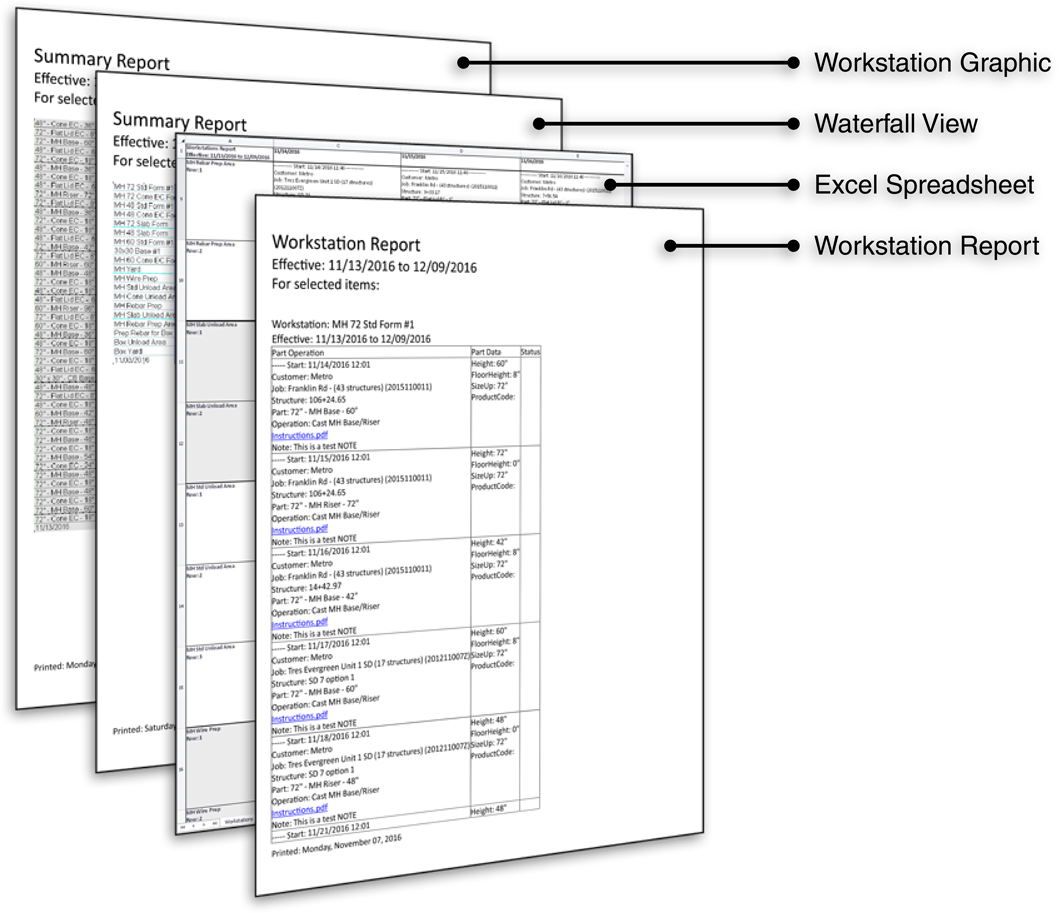

Configurable Reports

Paperless is great, but let's be honest, sometimes you need hardcopies. Foreman and Scheduler both have highly configurable print engines.

Want a graphic of your entire factory production? How about only a portion of the schedule? How about detailed reports on a workstation by workstation basis? Or maybe detailed reports that show you exactly what processes and locations that an individual part will pass through? If any of those sound familiar, we have you covered.

What about exporting options? We also have built in the capability to export the details of your factory schedule to an excel spreadsheet for easy data transfer to any other applications your business relies on.

Configurable Reports

Paperless is great, but let's be honest, sometimes you need hardcopies. Foreman and Scheduler both have highly configurable print engines.

Want a graphic of your entire factory production? How about only a portion of the schedule? How about detailed reports on a workstation by workstation basis? Or maybe detailed reports that show you exactly what processes and locations that an individual part will pass through? If any of those sound familiar, we have you covered.

What about exporting options? We also have built in the capability to export the details of your factory schedule to an excel spreadsheet for easy data transfer to any other applications your business relies on.

Full Circle

When you mark work as complete in Foreman the status is transmitted back to Scheduler and then back to STACK-IT. The flow of information from where the work is taking place back to the office is crucial to staying on top of your business.

Foreman brings you full circle, enables, and expedites the realtime flow of information.

Be Flexible

It's important to plan what workstation in your factory will build a part, but it's equally important to be flexible. If you've ever had to change molds or the physical location of where a part is built then you know the pain. Foreman let's you freely move work from one workstation to another as required to stay on schedule and will notify the rest of the Production Suite of the move.

System Wide Communication

Change availability of factory resources and the rest of the Production Suite will respond accordingly.

Team Focused

Have a large factory? We've got you covered with Foreman. The Production Suite supports as many installations of Foreman as you need. Mark work as complete, request schedule changes, change workstations from any computer connected to your network.

Modeler

Modeler is where you define your factory flow, mapping the workstations and operations for producing your products. This production roadmap gives Scheduler the know-how to route parts when building the schedule.

The power of modeling your factory

Every factory and production line is unique, and your software should accomodate your business, not force you into one way of operating.

Modeler is where you define your factory, your work processes, the flow of how you build parts. If Scheduler is the brain of Production Suite, Modeler is the map. Beyond the initial modeling of your factory you can use Modeler to maintain the online/offline status of your workstations and your operating hours.

The power of modeling your factory

Every factory and production line is unique, and your software should accomodate your business, not force you into one way of operating.

Modeler is where you define your factory, your work processes, the flow of how you build parts. If Scheduler is the brain of Production Suite, Modeler is the map. Beyond the initial modeling of your factory you can use Modeler to maintain the online/offline status of your workstations and your operating hours.

A flow for every part

Every part is different, but many are made the same way. In Modeler you will group parts by "family" and define the flow of how the parts in that family are made. The flow for a part family includes the workstations used, takt times, work instructions, specifications, and any other documentation that is relevant to each work step.

Visualize your factory

The top half of Modeler provides you with the ability to visualize the physical layout of your factory, and will even show you the path that a part family will travel through as parts are built. Get unique insights into your production process and identify opportunities to increase your efficiency.

Documentation on demand

Part of your factory model may include any and all production documentation that is needed for a particular part family. Attach notes and instructions to the process steps you define in Modeler to be included on reports generated by Scheduler or Foreman.

Expand your resources easily

As your business expands to include more workstations for building parts, or you add more parts to your catalog, they can easily be incorporated in to your existing factory model. Once your model is updated Scheduler will automatically begin using any additional available capacity.